Three Pass Fire Tube Steam Boiler/Hot Water Boiler

WNS gas/oil boiler adopts horizontal fire tube structure, which can provide larger steam/water output. Three pass wet-back design, larger corugated furmace, thread smoke tube with unique expansion welding technique, high quality and environmental protection.

| Output: | Steam, Hot-water |

| Capacity: | 0.1ton-40ton, 100kg-40000kg, 99kw-28000kw |

| Work Pressure: | 3-38bar, 0.3-3.8Mpa |

| Heat Temperature: | 0-450℃ |

| Applied Industry: | Food, Beverage, Feed, Textile, Paper, Chemical, Package, Refinery, Pharm, Building Material, Hotel... |

WNS Boiler Introduction

WNS horizontal gas/oil fired fire tube boiler, is a primary heating plant to generating steam or hot water. Certified by ASME CE ISO DOSH EAC TUV BUV. High quality, automatic control, 20+ years life assurance.

It is a must-have machine in a wide range of fields like Food, Beverage, Textile, Paper, Chemical, Refinery, Argo, Rubber&Plastic, Foam, Garment, Hotel, Pharm, Packaging, Laundry, Hospital etc...

●3 pass wet-back structure, larger corugated furmace, thread smoke tube with unique expansion welding.

●Equipped with international first-level brand burner & accessories.

●PLC automatic control, interlock system for burner, water tank, pressure, flame.

●Energy saving device, such economizer, condenser, preheater, condensate water recovery etc.

01

High Security, 100% Safe Operation

①Anti-dry heating system with five stages water level check; ②Four stages pressure protection; ③Explosion-proof door with fire viewer; ④Remote monitoring system.

02

98.6% High Efficiency, Save Fuel & Running Cost

①Large corrugated furnace, patent design three pass smoke tubes; ②Built-in steam separator, ensure high steam quality with wetness below 1%; ③Double 12mm thickness aluminum silicate insulation layer; ④Finned tube design economizer with aluminum silicate insulation, greatly reducing heat loss.

03

Long Using Life and Convenient for Maintenance

①Wet-back reverse flame chamber;②Solid round steel tension rod design;③Rapid solidification and high-strength refractory building materials;④Double opening-door at front and back.

04

Skid-mounted/Container Boiler, Quick into Use

It can be made to skid mounted boiler or mobile container boiler. Pre-installed in the factory, easy for transportation and installation, customers only connect water, electricity, fuel at site

① Water level protection, flame out protection, pressure protection, exhausted smoke over temperature protection, beside with 5th water level detector;

② Automatic operation of the burner ignition, flameout, big/small fire switch;

③ Steam-water separator, high steam quality with wetness below 1%

④ Water quality protection (dosing device, TDS system optional)

① SZS water tube steam and hot water boiler, 5-100 ton/h, water membrane wall design, high efficiency 98%, larger combustion furnace.

② LHS LSS Small gas/diesel boiler, vertical boiler, gas/diesel steam and hot water generator.

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Transportation一We have shipping partners and forwarder for lowest price and safe.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Why Choose Us

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Parameter

| Model | Capacity | Rated steam output | Rated pressure | Rated temperature | Feed water temperature | Fuel consumption | |

| (kg) | (Ton/hr) | (Mpa) | (℃) | (℃) | Light diesel oil(kg/h) | Natural gas(Nm3/h) | |

| WNS0.5 | 500kg | 0.5 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0 mpa | 130~171 | 20/105 | 32 | 42.5 |

| WNS0.7 | 700kg | 0.7 | 130~171 | 20/105 | 49.5 | 51 | |

| WNS1 | 1000kg | 1.0 | 130~185 | 20/105 | 70 | 80 | |

| WNS1.5 | 1500kg | 1.5 | 130~185 | 20/105 | 108.7 | 115.4 | |

| WNS2 | 2000kg | 2 | 130~185 | 20/105 | 135.2 | 150.4 | |

| WNS3 | 3000kg | 3 | 130~226 | 20/105 | 192.9 | 212.1 | |

| WNS4 | 4000kg | 4 | 130~226 | 20/105 | 258.2 | 283.4 | |

| WNS5 | 5000kg | 5 | 130~226 | 20/105 | 323.5 | 354.7 | |

| WNS6 | 6000kg | 6 | 130~226 | 20/105 | 388.6 | 424.2 | |

| WNS8 | 8000kg | 8 | 130~226 | 20/105 | 514.6 | 566.3 | |

| WNS10 | 10000kg | 10 | 130~226 | 20/105 | 641.7 | 707.8 | |

| WNS12 | 12000kg | 12 | 130~226 | 20/105 | 768.9 | 849.3 | |

| WNS15 | 15000kg | 15 | 130~226 | 20/105 | 960.1 | 1061.7 | |

| WNS20 | 20000kg | 20 | 130~226 | 20/105 | 1276.2 | 1415.8 | |

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Output water temperature (℃) |

Return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| WNS 0.35 | 0.35mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 31.6 | 36.6 |

| WNS 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 60.4 | 69.3 |

| WNS 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 122.8 | 146.1 |

| WNS 2.1 | 2.1mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 192.3 | 227.1 |

| WNS 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 246.1 | 286.5 |

| WNS 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 367.1 | 412.6 |

| WNS 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 490.2 | 543.7 |

| WNS 7.0 | 7.0mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 593.6 | 660.7 |

| WNS 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 936.5 | 998.8 |

| WNS 14 | 14mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 1200.8 | 1330.7 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Recommend Boiler

Skid-mounted Boiler

Skid-mounted steam boiler and hot water boiler systems represents an all-in-one, ready-to-operate boiler solution.

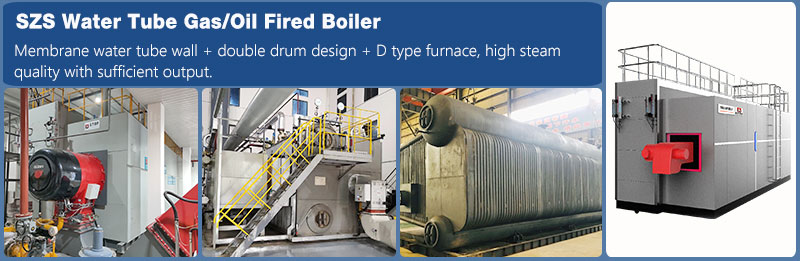

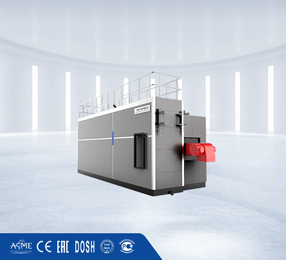

SZS Water Tube Boiler

SZS water tube packaged gas/oil boiler, larger furnace with light membrane wall, high efficiency

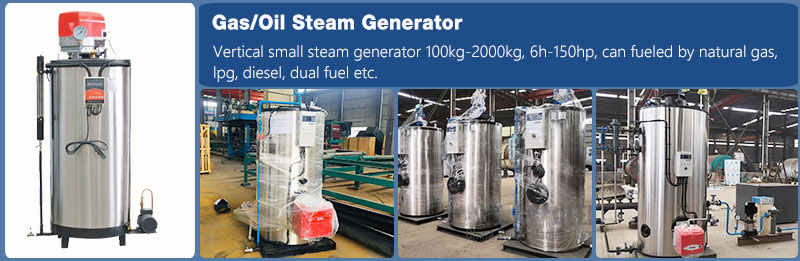

Vertical Oil / Gas Boiler

More suitable for: small space, low budget, OR steam demand of 100 to 2000 kg/h, 120 to 1400 kw/h

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler