Fuel options:Gas, Diesel, Biomass, Coal, Wood, Charcoal, Briquette, Electric ...

Industrial steam boiler is an important heating equipment for factory production, popular in all the needs of steam, hot water, hot oil. Widely used in food/beverage, paper making, packaged, textile, feed mill, refinery, chemical, building materials, laundry, hotel and other industries.

| Layout: | Horizontal, Vertical, Skid Mounted, Container |

| Capacity: | 0.1 - 50ton, 80 - 28000kw |

| Work Pressure: | 3-38bar, 0.3-3.8Mpa |

| Heat Temperature: | 0-450℃ |

| Applied Industry: | Food, Beverage, Feed, Textile, Paper, Chemical, Package, Refinery, Pharm, Building Material, Hotel... |

Reliable High-Temperature Industrial Heating Solution

Steam boiler(steam generator) is a must-have machine in factory production like Food, Beverage, Textile, Paper, Chemical, Refinery, Argo Industry, Sugar Mill, Oil Mill, Rubber&Plastic, Foam, Garment, Hotel, Pharmaceutical, Packaging, Laundry, Hospital etc...

It can generating steam or hot water for industrial, commercial and other specialized uses.

PS: If you require thermal oil heating system, please view https://www.boilerindustrial.com/product/Industrialboiler-Thermaloilboiler.html

Yuanda Boiler provides high-efficiency, high-quality industrial boilers that support a variety of fuel types, including natural gas, lpg, diesel, heavy oil, electricity, coal, firewood, rice husk, palm shells, palm fiber, EFB, biomass pellets, and wood waste, sawdust, shavings, to meet different customer needs.

All equipment is ASME, CE, ISO, DOSH, EAC, and CRN certified, conforming to international standards.

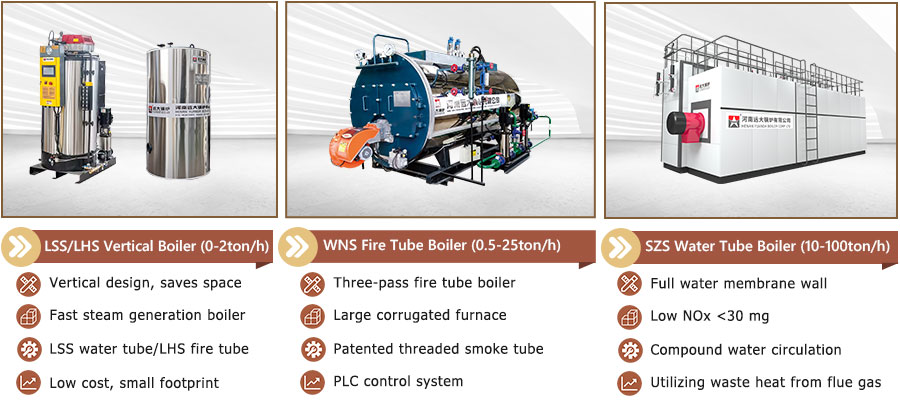

• Gas/Oil Fired Boiler Series: WNS fire tube boiler, SZS water tube boiler, LHS/LSS vertical design boiler

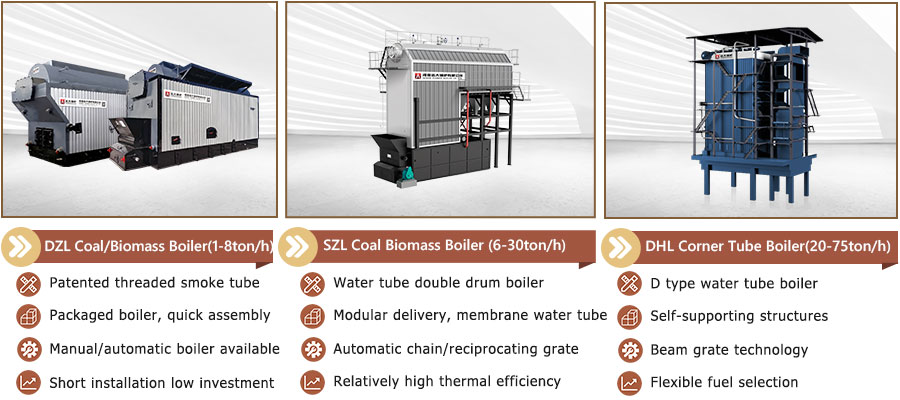

• Coal Fired Boiler Series: DZL/SZL chain grate boiler, CFB circulating fluidized bed boiler, DHL corner tube boiler

• Wood/Biomss Boiler Series: DZH manual feeding boiler, DZL/DZW fire tube structure boiler, SZL/SZW water tube boiler, BFB bubbling fluidized bed boiler, DHL corner tube boiler

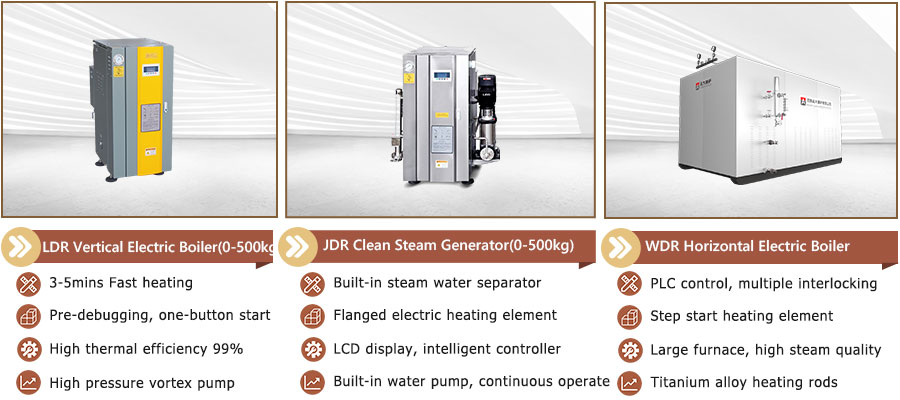

• Electric Boiler Series: LDR vertical electric boiler, WDR horizontal electric boiler

LHS/LSS vertical design gas/oil fired boiler; WNS horizontal gas/oil fired boiler; SZS water tube gas/oil fired boiler(A superheater can be added).

DZH/DZL fire tube coal biomass boiler; SZL/SZW water tube double drum boiler; DHL corner tube coal biomass boiler.

LDR vertical electric boiler; JDR clean type steam generator, stainless steel steam generator; WDR horizontal electric boiler.

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

Our Service

From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model |

Capacity (Ton/h) |

Horspower (hp) |

Pressure (Mpa) |

steam temperature (℃) |

Feed water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | ||||||

| WNS 0.5 | 0.5 | 35 | 0.4 to 3.82mpa | 130~450 | 20/105 | 32.5 | 35.7 |

| WNS 1 | 1 | 71 | 0.4 to 3.82mpa | 130~450 | 20/105 | 64.6 | 70.1 |

| WNS1.5 | 1.5 | 120 | 0.4 to 3.82mpa | 130~450 | 20/105 | 96.8 | 105.2 |

| WNS 2 | 2 | 150 | 0.4 to 3.82mpa | 130~450 | 20/105 | 129.3 | 140.3 |

| WNS 3 | 3 | 200 | 0.4 to 3.82mpa | 130~450 | 20/105 | 192.9 | 212.1 |

| WNS 4 | 4 | 300 | 0.4 to 3.82mpa | 130~450 | 20/105 | 258.2 | 283.4 |

| WNS 5 | 5 | 350 | 0.4 to 3.82mpa | 130~450 | 20/105 | 323.5 | 354.7 |

| WNS 6 | 6 | 425 | 0.4 to 3.82mpa | 130~450 | 20/105 | 388.6 | 424.2 |

| WNS 8 | 8 | 550 | 0.4 to 3.82mpa | 130~450 | 20/105 | 514.6 | 566.3 |

| WNS 10 | 10 | 700 | 0.4 to 3.82mpa | 130~450 | 20/105 | 641.7 | 707.8 |

| WNS 12 | 12 | 850 | 0.4 to 3.82mpa | 130~450 | 20/105 | 768.9 | 849.3 |

| WNS 15 | 15 | 1050 | 0.4 to 3.82mpa | 130~450 | 20/105 | 960.1 | 1061.7 |

| WNS 20 | 20 | 1400 | 0.4 to 3.82mpa | 130~450 | 20/105 | 1276.2 | 1415.8 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | |||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler