DHL DHW boiler | Multi-fuel boiler | Corner tube boiler

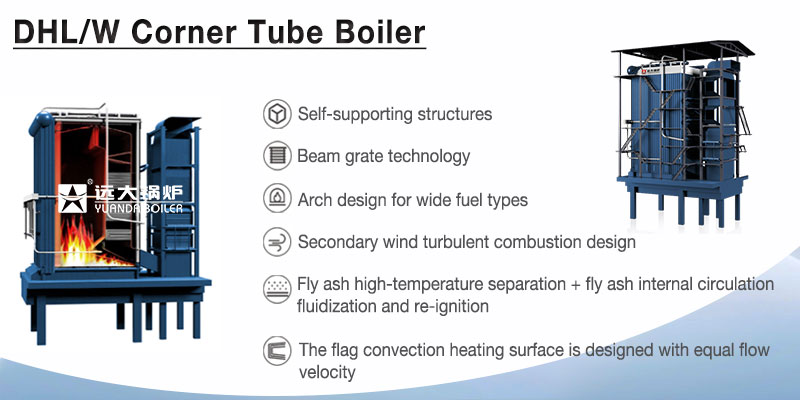

The DHL DHW corner tube boiler, also known as D-type boiler, capacity from 20 tons to 75 tons. Corner tube boilers are self-supporting structures that do not require additional steel supports; flexible fuel selection, suitable for co-firing of various fuels, ideal for power generation, heating, sugar refining, chemicals, food, and rubber.

| Output: | steam/hot water |

| Capacity: | 20 ton/h-75 ton/h |

| Work Pressure: | 1.25mpa to 4.0mpa |

| Available Fuel: | coal, biomass, woodchip, palm shell/fiber, EFB, rice husk, bagasse, forest waste, mixed fuel... |

| Applied Industries: | power generation, heating, chemicals, food, rubber, sugar refinery, palm oil mill... |

Introduction

Henan Yuanda Boiler's DHL/DHW corner tube boiler are high-efficiency industrial boiler, suitable for burning coal, bulk biomass, woodchips, sawdust, fruit shells, bagasse, palm fiber, EFB(empty fruit bunches), and other solid fuels.

D-type water-tube boiler design, robust and durable, offering high thermal efficiency, low operating costs, long-term trouble-free operation, low dust emissions, lightweight construction, low infrastructure investment, and direct sales from the manufacturer. It can supply steam/hot water reliably or be used for combined heat and power (CHP).

Furthermore, due to its self-supporting structure, on-site installation requires minimal effort and short installation cycle. These features make it a modern alternative to large-capacity steam/hot water boilers.

Applications: Power generation, heating, chemical industry, food processing, rubber, sugar mills, palm oil mills, etc.

I. Technical Advantages

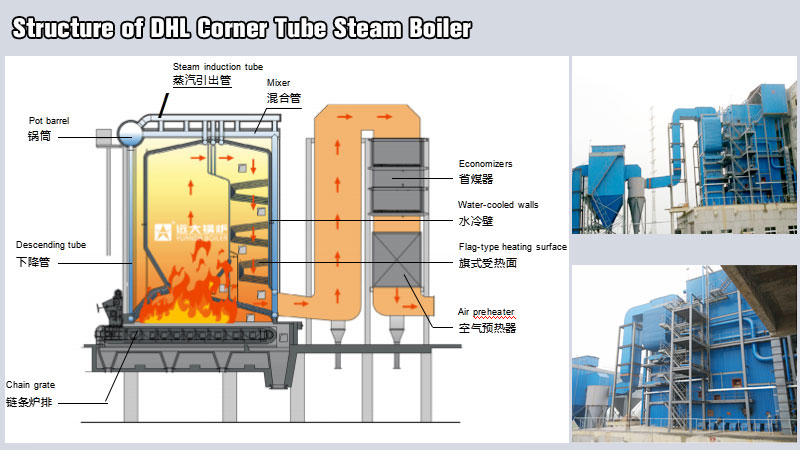

① Robust Steel Frame — The angle tube boiler adopts a frameless structure, with the entire weight supported by membrane water-cooled walls and downcomers, providing excellent seismic resistance. The boiler body has a design life exceeding 20 years.

② Reliable Water Circulation — The unique recirculation pipe and steam outlet pipe design offer high pressure resistance, faster and safer water circulation start-up.

③ Excellent Fuel Adaptability — With the matching stoker grate (such as chain grate or reciprocating grate), it can efficiently burn a wide range of fuels, from bituminous coal and anthracite to various forms of biomass (wood chips, straw, palm shells, EFB, coconut shell etc.), allowing for flexible fuel selection based on cost and policy.

④ High-Efficiency Combustion — The optimized furnace structure and air distribution system ensure complete combustion of both coal and biomass.

⑤ Compact Convection Arrangement — The transverse multi-pass flue gas flow through tightly arranged convection tube bundles provides a long and sufficient heat exchange path. Combined with the tail-end economizer, it effectively controls the exhaust gas temperature, maintaining high system thermal efficiency.

⑥ High-Quality Steam Output — Pre-separation of gas and water is performed in the steam overflow system, resulting in very high steam dryness.

II. Operational and Economic Advantages

① Control over Costs — Coal can be used when prices are low, and biomass can be switched to or blended when biomass resources are abundant and environmental requirements are high, reducing fuel costs.

② Intelligent Control — Equipped with an advanced PLC/DCS control system, it can achieve automatic feeding, air supply, regulation, and safety interlocking.

III. Installation and Maintenance Advantages

① Factory Prefabrication — Large components such as membrane water-cooled walls, headers, and convection tube bundles are prefabricated in the factory. On-site installation work mainly involves hoisting and splicing, reducing on-site construction difficulty and costs.

② Easy Inspection and Cleaning — Sufficient inspection doors, observation holes, and ash removal ports are designed for easy inspection and maintenance of the furnace and heating surfaces. The spacing of the convection tube bundles is reasonable, facilitating ash removal.

IV. Environmental Advantages

By optimizing the furnace structure and air distribution, and combining it with a multi-stage flue gas purification system (such as dust removal, desulfurization, and denitrification), it can meet stringent environmental emission standards.

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model | Steam Capacity(t/h) | Rated Pressure (Mpa) | Rated Steam Temeperature (℃) | Thermal Efficiency(%) | Design Fuel |

| DHL20 | 20 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | coal, biomass, wood chips, biomass pellet, bagasse, rice husk, palm kernel shell etc. |

| DHL25 | 25 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL30 | 30 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL35 | 35 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL40 | 40 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL50 | 50 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL75 | 75 | 1.25/1.6/2.0/2.5/3.82/5.3 | 194/204/250/320/450 | 89—92 | |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | |||||

| Boiler Model | Rated Thermal Power(MW) | Rated Working Pressure(MPa) | Rated Outlet Water Temperature (℃) | Rated Intake Temperature (℃) | |

| DHL29-1.25/130/70-M | 29 | 1.25 | 130 | 70 | |

| DHL46-1.6/150/90-M | 46 | 1.6 | 150 | 90 | |

| DHL58-1.6/150/90-M | 58 | 1.6 | 150 | 90 | |

| DHL70-1.6/150/90-M | 70 | 1.6 | 150 | 90 |

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler